What is Reverse Logistics? A Guide to Optimizing Your Returns Process

In 2023, efficient shipping and delivery are no longer enough to secure ecommerce success; you also need a seamless returns process on both the customer and logistics side.

This is crucial because returns are rising, with the average return rate for online purchases in 2022 sitting at 20.8% (up from 18.1% in 2021).

Additionally, more than 60% of customers check a brand’s returns policy before making a purchase decision. These figures reflect an alarming rate of lost sales opportunities and the effect of returns on consumer behavior.

With online retail sales forecasted to reach $6.51 trillion in 2023 and ecommerce accounting for 22.3% of total retail sales, we can expect returns to grow alongside it.

This significant component of ecommerce opens the opportunity to transform your returns into a competitive advantage for your business, and we’ll show you how.

Read on to learn more about:

- What reverse logistics is and how it works

- Reverse logistics examples

- Advantages & challenges of reverse logistics

- Best practices for reverse logistics

- Reverse logistics solutions

#cta-visual-pb#<cta-title>Create seamless experiences<cta-title>Use Shogun Page Builder to create a website that runs as smoothly as your reverse logistics.Start building for free

What is reverse logistics?

Although reverse logistics involves dealing with returns, it encompasses much more, including:

- How you reincorporate returned products into your inventory pool

- How to streamline your logistics (both forward and reverse)

- The data, inventory management, and tracking of items that come back

- Your strategy behind the returned products

Reverse logistics plays an important role in more than just customer returns. It isn’t just the opposite of traditional logistics.

For instance, it’s also crucial for rental businesses, items that come back after a trial period, unsold goods from retailers, and undeliverable products.

How does reverse logistics work?

To better grasp how it works, you’ll need to learn the various elements of reverse logistics.

Key components

Below are the critical components of reverse logistics, from your policies to packaging and physical operations.

Return policy and procedure (RPP)

Your return policy conveys your rules and regulations for customer returns. It should contain and clearly state the following three standard components:

- A return time frame

- The required proof of purchase

- A form of refund

For example, if someone wants to send an item back, but the return period in your policy has passed, their request would be deemed invalid.

On the other hand, with a valid request, showing a receipt and/or ID is necessary to have the refund processed.

Packaging management

These processes focus on reusing packing materials for returned items and minimizing waste and expenses you’d otherwise incur for new ones.

How you recycle or reuse returned viable packaging can help you conserve resources, but be sure to maintain the same pristine buyer experience and avoid cutting corners.

Returns management

This is the most ubiquitous process in reverse logistics.

It encapsulates how you handle customer returns and building out these operations is your opportunity to make them as frictionless as possible.

Returns management encompasses where you direct returns, the procedure you have in place for processing returns, and the checks and balances to ensure no sub-par goods go back out into circulation.

Standardizing these operations can help you optimize your returns management for a more streamlined process.

The returns process

Here’s what a typical returns procedure looks like.

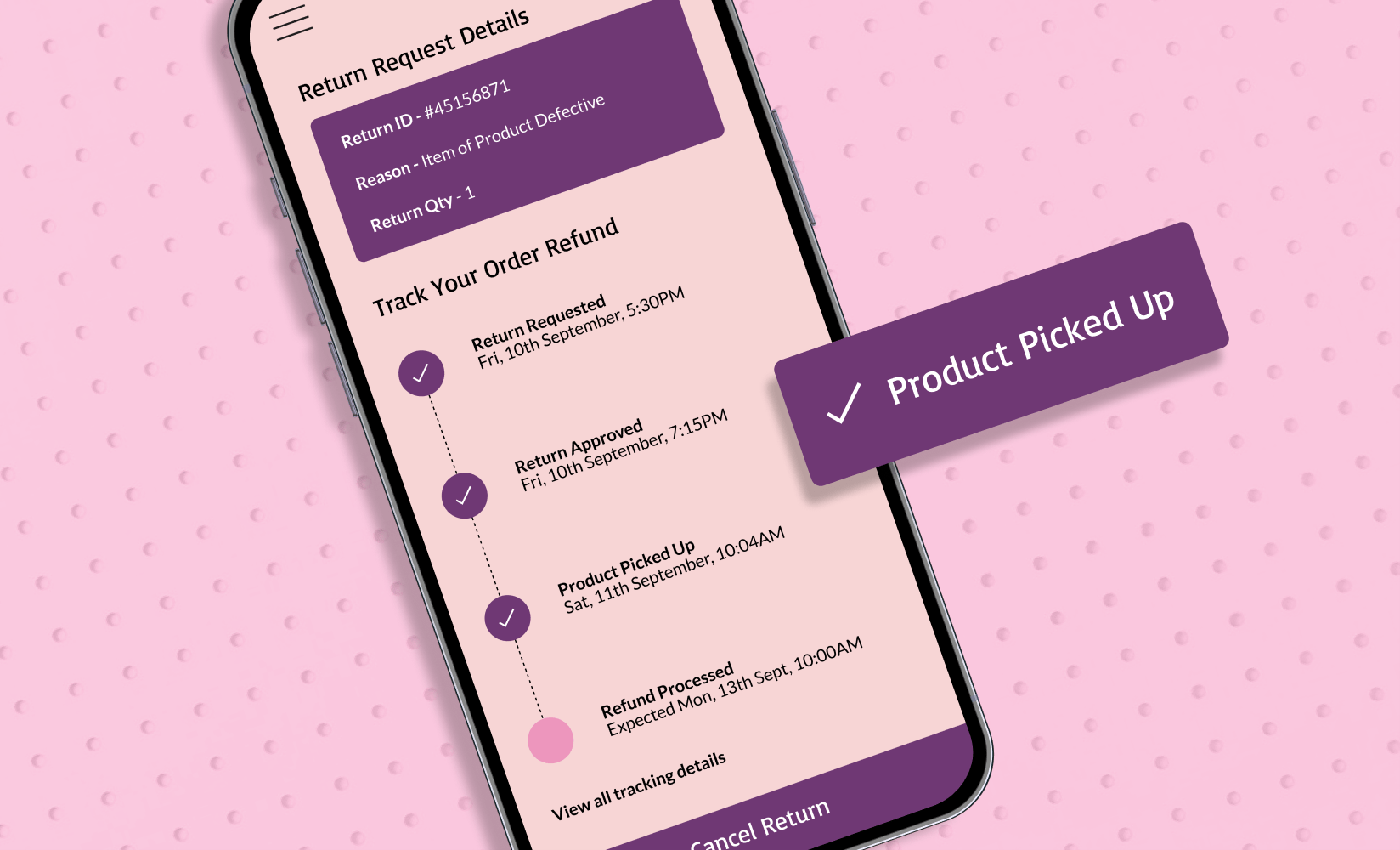

Step 1: Processing

When a customer initiates a return, you have to determine why.

Then, you need to define the appropriate steps the product will follow once it’s out of your customer’s possession.

In this step, you coordinate the item’s transportation and, if you offer free returns, pay for it. Planning, meanwhile, minimizes expenses and your environmental footprint.

For instance, driving a vehicle for a single-item return—such as picking up a mattress that a customer has decided to return at the end of their trial period—is wasteful and costly since it fails to maximize the vehicular space.

Tip: At the beginning of your returns process, ask customers why they’re unsatisfied with your product. This reveals valuable insight for your product development team.

Step 2: Categorizing

Upon receiving the returned item, you examine it to determine where it goes next. Asking the customer to provide the reason for their return in the previous step speeds up the process.

At this stage, you aim to identify whether the item needs to be sent in for:

- Repair and maintenance: The item is broken, but you can fix it and either send it back to the customer or resell it.

- Replacement: An item is irreparably broken or unusable, but the customer wants a replacement instead of their money back.

- Disposal: The item is unfixable and has no further use. Consider salvaging working parts from these items to fix others, especially if you have a warranty program.

- Exchange: A product is returned, and the customer wants a different item to replace it. These items may still be in good condition, depending on the reason for the exchange (for example, they want a different color or size).

Step 3: Moving

Next, it’s time to move the item physically to a designated area.

For example, if a product was returned because it was defective or malfunctioning, it should be forwarded to the repair or refurbishing department.

Keep in mind this inventory shouldn’t sit too long in holding or it’ll quickly turn into aged inventory and lose even more value.

It might even end up as waste accidentally.

Tip: Consider having all of your reverse logistics processes centralized in one warehouse. That way, you have a standard address for all returns, and that warehouse can be trained in your processing procedures to ensure minimal inventory waste.

Step 4: Taking action

Once the returned product reaches the appropriate department, here’s what you can do next:

- If it’s under warranty, it can either be repaired or replaced, then shipped back to the customer. With this option, you track the item until it’s back in the customer’s hands.

- If the customer asks for a refund, send it. Afterward, you can repair, refurbish, and reincorporate the returned item into your inventory. In this case, you track it as it makes its way back into your stocked goods.

- If the product can’t be saved, you can disassemble it and recycle some parts or dispose of it completely. Anything that’s reusable can be applied to goods sent in for repair. You track those parts and the disposable components until they’re out of your hands.

Step 5: Reselling or disposing

After the above steps, the items you’ve reincorporated into your inventory can be remarketed and resold.

This minimizes losses and can even turn your lost sale into profit.

As for unsalvageable items, simply monitor them until they’re properly disposed of. Being diligent improves your sustainability and helps you track your inventory and finances.

The cost

The vital consideration for reverse logistics is its implementation cost: A return can cost you 66% of the product’s original price.

You also have to account for spending on transport, labor, and proper disposal.

However, the long-term benefits of robust reverse logistics outweigh the initial pinch to your wallet.

Moreover, mastering reverse logistics helps reduce your carbon footprint. With environmental impact affecting 30% of consumers’ purchasing decisions, investing in sustainability can bring big returns.

Types of reverse logistics

Now that you have a general understanding of reverse logistics, let’s break down its various forms.

End-of-life (EOL)

A product at its EOL fits one of the following criteria:

- It no longer fulfills a customer’s needs

- The item no longer works

- A newer, better version has replaced it

- The product has simply reached the end of its usefulness

Some items at their EOL need to be returned to their manufacturers for proper disposal, which can cost money.

Straight returns

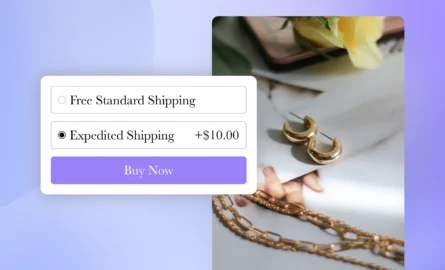

A straight return entails a customer sending back a product in exchange for a refund.

In this scenario, you forfeit the sale and pay the cost of shipping, which can eat into your bottom line.

#cta-mini-pb#Learn how to prevent returns in the first place. Learn more

Warranty returns

Warranties serve as guarantees, promising customers the product will perform. Coverage, meanwhile, can last from days to a lifetime.

If the purchased items don’t work as expected or have issues under warranty, customers can send them back for repair or replacement.

Once done, you send the products back (at your expense).

Exchanges

Exchanges also involve customers returning purchases, but they’re replaced with a different item.

When a shopper receives an incorrect order—such as a shirt in the wrong color—they can send it back and swap it for the right one or exchange it for store credit.

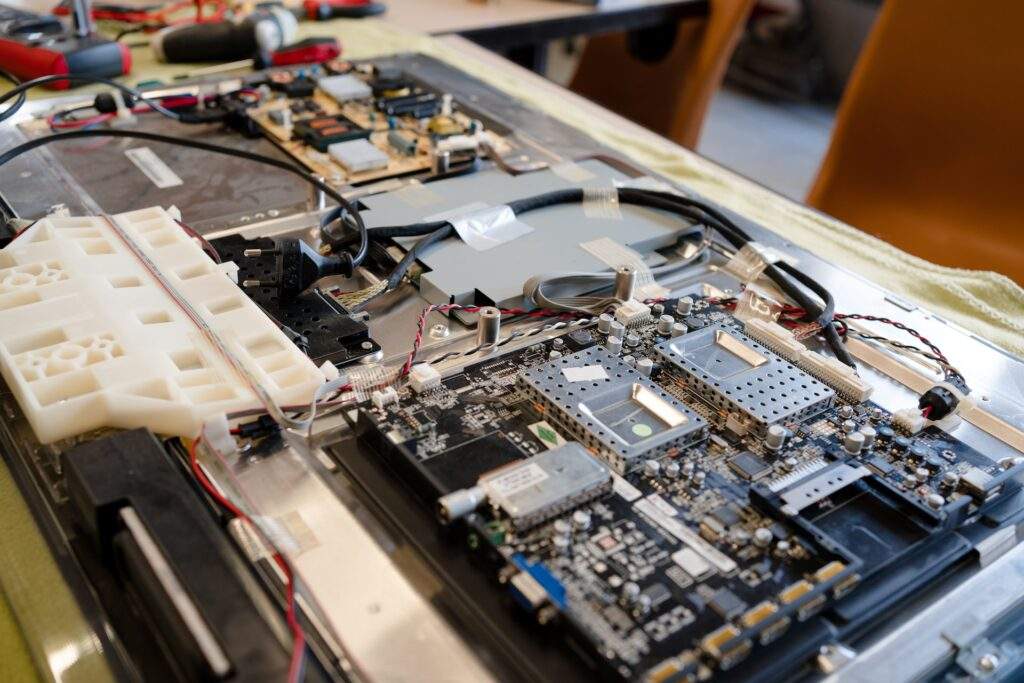

Refurbishment, repairs, or remanufacturing

This form of reverse logistics entails repairing, refurbishing, or remanufacturing damaged products that have been sent back, then reselling them.

For instance, when someone returns a defective or broken item, its interchangeable and reusable parts are recovered and repurposed to prevent unnecessary waste.

Next, they’re reassembled, incorporated into working products, and then sold to minimize losses.

Rental returns

As for rented or leased goods returned at the end of their agreed-upon term, you can assess them for damage, then recondition and remarket them.

If you can’t redeploy them though, recycle or dispose of the items.

Unsold goods

This type of reverse logistics involves retailers returning unsold products to distributors or manufacturers.

Companies commonly resort to this option due to poor sales, delivery refusal, inventory obsolescence, or other factors.

Delivery failure

For this form of reverse logistics, items that can’t be delivered are returned to distribution centers.

Then, they’re either returned to their point of origin or, for more capable companies, resent to customers after the cause of delivery failure is identified and corrected.

#cta-mini-pb#Prevent delivery failures with resilient logistics. Learn more

Benefits of successful reverse logistics

With this more detailed view of reverse logistics, let’s delve into how this process can benefit you, your customers, and the environment.

Better inventory management

Well-executed reverse logistics can help you track and reincorporate otherwise wasted inventory.

It lets you identify what’s recoverable from a lost sale to minimize overall losses.

Additionally, you don’t have to reorder or remanufacture products or specific parts as frequently when you make the most of returned inventory.

Improved sustainability

Since you repair, refurbish, and recirculate items that would have otherwise been disposed of, you reduce your company’s waste.

This circular economy can positively impact sustainability, especially with the increasing number of environmentally conscious businesses and consumers:

- A 2022 study of 850 companies around the world showed 80% of them intend to invest more in sustainability.

- Over half of consumers (56%) care “somewhat” or “a lot” about the environmental impact of returns.

These figures show adopting green practices is both more eco-friendly and beneficial for your brand.

Tip: Consider reusing what you can of your dunnage and packaging as well, especially if you will resell returned items at a discount.

Increased customer satisfaction

The returns process is also a crucial element of customer retention.

In fact, 95% of consumers say a poor experience makes them less likely to purchase from a brand again.

Guaranteeing a seamless experience for your shoppers serves as powerful reassurance that can close a sale, especially for online buyers since they can’t see or touch the products they purchase.

It also reduces consumer stress and increases word-of-mouth recommendations, thus expanding your potential customer reach.

Challenges of reverse logistics

Despite its upsides, reverse logistics has some notable drawbacks.

Greater complexity

Executing reverse logistics requires you to manage a second fulfillment path for your items.

In addition to items going to consumers, you have to incorporate tracking and processes for those coming back.

This expands the complexity of your fulfillment process, which in turn opens up more opportunities for mistakes.

You can (and should) incorporate tools to handle all of that, but this adds yet another element to oversee.

Harder to oversee quality control

Unless you have stringent and uniform quality control measures in every channel that accepts returns, you may receive an item that’s worn, damaged, or has missing pieces and that slip past conditional review.

If you fail to flag a defective item for refurbishment or disposal or, worse, send it to a new customer, you risk your brand reputation with poor-quality returned goods.

Negative reviews (when done poorly)

Everyone makes mistakes, but when they occur in logistics—such as losing an item or not refunding a return—they can result in negative reviews.

Poor feedback can hurt your business since around 13% of unhappy customers share their bad experiences with 20 people on average.

In essence, when you do wrong, word gets around.

Reverse logistics best practices

Although the challenges outlined above may seem formidable, you have a few options to counter them. Here are some tips to help you take preventive measures.

Craft an airtight return policy

Clearly communicate and strictly enforce the terms of your return policy to help both your customers and employees avoid confusion.

Be firm about the valid return period, proof of purchase requirements, the form of refund, and other points to keep the process seamless.

This adherence also prevents fraudulent activity, such as online shoppers abusing your policy to snag refunds or free goods.

Designate accountability

Another way to optimize your reverse logistics is to partner with a fulfillment provider to handle returns.

Having a single fulfillment path to track cuts down on the complexity of your logistics.

Be sure to hold your partner accountable so that if anything goes wrong, they can’t pass the blame. When they shoulder the responsibility, you can focus on other parts of your reverse logistics process for smooth operations.

Reduce waste

Wherever possible, consider how to reduce waste while protecting your customer experience.

For example, if you receive unsellable inventory, can you disassemble it and salvage parts to repair goods that come back under warranty?

Centralize returns

Designate a space equipped to handle and process returns, as this will improve quality control and tracking.

Dedicating an area for this procedure also protects your buyer experience, as you can train employees to specialize in returns, such as what to watch for when validating a return or assessing an item’s condition.

Invest in quality control

Don’t hesitate to spend on quality control.

Having foolproof review measures and people capable of enforcing high standards will benefit both your customers and your business as a whole.

For instance, when an item is sent back in poor condition, your stringent process will ensure the return is passed on to a new customer in a better state. This protects your brand and minimizes losses and waste.

Choose the right software

Although reverse logistics is a complicated affair, selecting the right tools that work with your overall ecosystem simplifies it.

Robust software can streamline your workflows and assist with tracking, shouldering a significant portion of the burden.

#cta-visual-pb#<cta-title>Showcase your reverse logistics<cta-title>Display your return policies, manage your returns, and more with Shogun Page Builder.Start building for free

Reverse logistics solutions

To help you find the best solution for your business, start with these, which are designed specifically for reverse logistics.

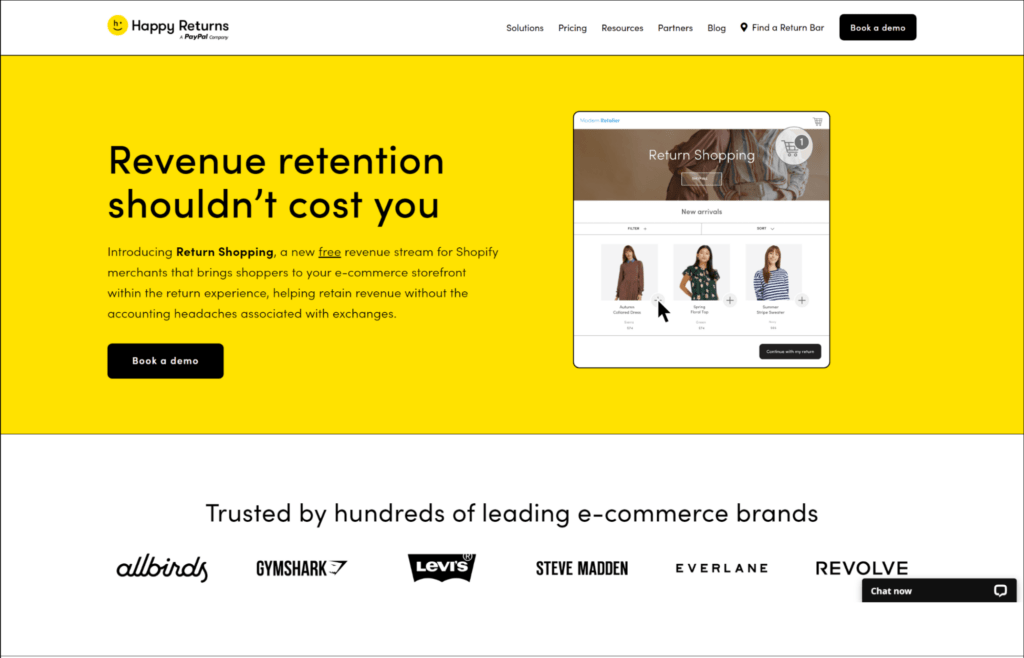

Happy Returns

Happy Returns helps ecommerce merchants retain revenue with the following reverse logistics tools:

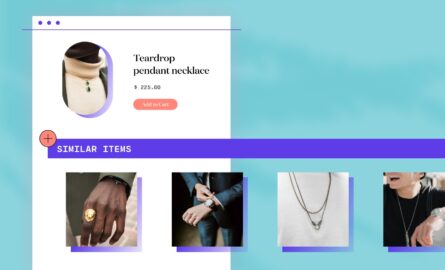

- Return & exchange portal: Automates and simplifies returns and provides a branded experience

- Return Bars network: Offers convenient refunds and exchanges, as well as box-free and label-free returns

- Return app: The Happy Returns app connects ecommerce orders to your physical stores, enabling streamlined omnichannel experiences

Pricing:

- Free for those who offer PayPal as a payment method

- Starts at $500 up to custom pricing

Loop

Loop’s platform offers a returns experience similar to online shopping, helping merchants minimize costs, prevent losses, and retain revenue. It also:

- Handles exchanges

- Provides automations

- Delivers insights

- Integrates with shipping and logistics providers

Pricing:

- Essentials – 500: $59/month

- Essential: $165/month

- Advanced: $375/month

Returnly

Returnly delivers a suite of tools for businesses to build a customized and branded returns center.

Engage customers at the point of return and offer a frictionless self-service experience.

The suite also integrates with shipping providers and Shopify, as well as possesses additional functionalities for:

- Exchanges

- Tracking

- Analytics

Pricing:

- Starter (App): $149/month; 1,000 returns/year; $3 per additional return

- Starter with SPI (App): $99/month

- Premium: Custom pricing

ReverseLogix

ReverseLogix provides ecommerce businesses with a returns management system (RMS) that takes care of the entire reverse logistics life cycle.

The platform boasts customizable workflows, automations, and integrations that:

- Deliver seamless return experiences

- Improve returns management

- Enable in- and out-of-warranty repairs

- Eases recommerce

Pricing:

- Custom pricing, need to get in touch with the company

Veho

Veho is a last-mile logistics platform that enables convenient doorstep returns through the following steps:

- A customer requests a return, chooses a pickup date, and provides instructions.

- Veho then sends them a time slot and collects the item from their doorstep.

- Lastly, Veho packs, labels, and ships the returned item to a merchant’s fulfillment center.

The process doesn’t require boxing or printing on the customer’s part; Veho takes on the burden for them.

Pricing:

- Custom pricing, need to get in touch with the company

Strengthen your reverse supply chain to generate forward business momentum

Developing a robust reverse logistics process is a complex and costly undertaking.

If done well, however, the benefits easily outweigh its challenges. You can minimize waste, turn lost sales into profit, and even boost your brand reputation.

Let the information we’ve provided serve as your starting point, then build on it according to your business’s needs.

Once you optimize your reverse logistics, you’ll see benefits for your brand, your consumers, and the world. By mastering supply chain management, you’ll be far ahead of the competition.

#cta-visual-pb#<cta-title>Create seamless experiences<cta-title>Use Shogun Page Builder to create a website that runs as smoothly as your reverse logistics.Start building for free

Rachel Go

Rachel is a remote marketing manager with a background in building scalable content engines. She creates content that wins customers for B2B ecommerce companies like MyFBAPrep, Shogun, and more. In the past, she has scaled organic acquisition efforts for companies like Deliverr and Skubana.