Fresh Supply Chain Trends for 2023: How to Pivot and Respond

To say the ecommerce supply chain is facing major disruption would be an understatement.

This past year, merchants scrambled to address how the supply chain was impacted globally. Global shipping, logistics, and fulfillment became very tricky to balance amid shoppers’ learned expectations around two-day or even same-day delivery.

It’s causing disruption for many ecommerce merchants. Six in 10 supply chain managers say their logistics aren’t operating as normal. But in worse news: some 29% say they don’t expect things to stabilize until 2025.

How can you respond to consumer demands and future-proof your supply chain without causing further disruption?

This guide is an up-to-date look at what’s happening with supply chain trends in 2023 and how established merchants should adapt their supply chain operations to keep things running as smoothly as possible.

Skip ahead:

- The state of supply chain management in 2023

- The most common supply chain challenges in ecommerce

- 6 Supply chain trends to support growth in 2023

The state of supply chain management in 2023

The supply chain industry is set to be worth $30.91 billion by 2026. But with such aggressive growth comes a constantly-changing environment.

Let’s dive deeper into the state of ecommerce supply chains in 2023:

- Disruption due to supply shortages increased 452% year-over-year, making it the biggest supply chain challenge for 57% of executives

- Supply chain disruption costs the average organization $184 million per year, but 8% of retailers say the financial damage is upwards of $500 million

- While lockdowns are over in most of the world, 35% of retailers say the aftermath of COVID-19 will still impact supply chains by 2025

- Despite this extreme and seemingly ongoing disruption, just 21% of organizations say they have a highly resilient supply chain network

What are the most common supply chain challenges in ecommerce today?

Ecommerce supply chains are volatile. Let’s dive deeper into four of today’s supply chain challenges causing friction for you and your customers.

Economic disruption

According to one McKinsey study, significant production disruptions—such as pandemics, cyber attacks, and trade tensions—happen every 3.7 years on average and cost businesses an average of $184 billion annually.

Two major events are still wreaking havoc with ecommerce supply chains. The first: COVID-19 aftershocks.

China, a country responsible for exporting $2.641 trillion worth of goods each year, is still under strict pandemic-induced lockdowns, causing a backlog of shipments and port disruptions. This port congestion is where most merchants experience disruption throughout their supply chain.

The Russia-Ukraine war is causing a threat to future supply chains, too. Pre-conflict, Russia was one of the world’s largest exporters of raw materials like fuel, oil, and precious metals. But sanctions on the country forced merchants to source materials elsewhere—a disruptive and expensive solution.

Inventory usually transported by air must also divert to avoid crossing closed airspace, and train routes in Russia are unavailable. Just one of these issues would be enough to send supply chain professionals into a frenzy.

Rising prices

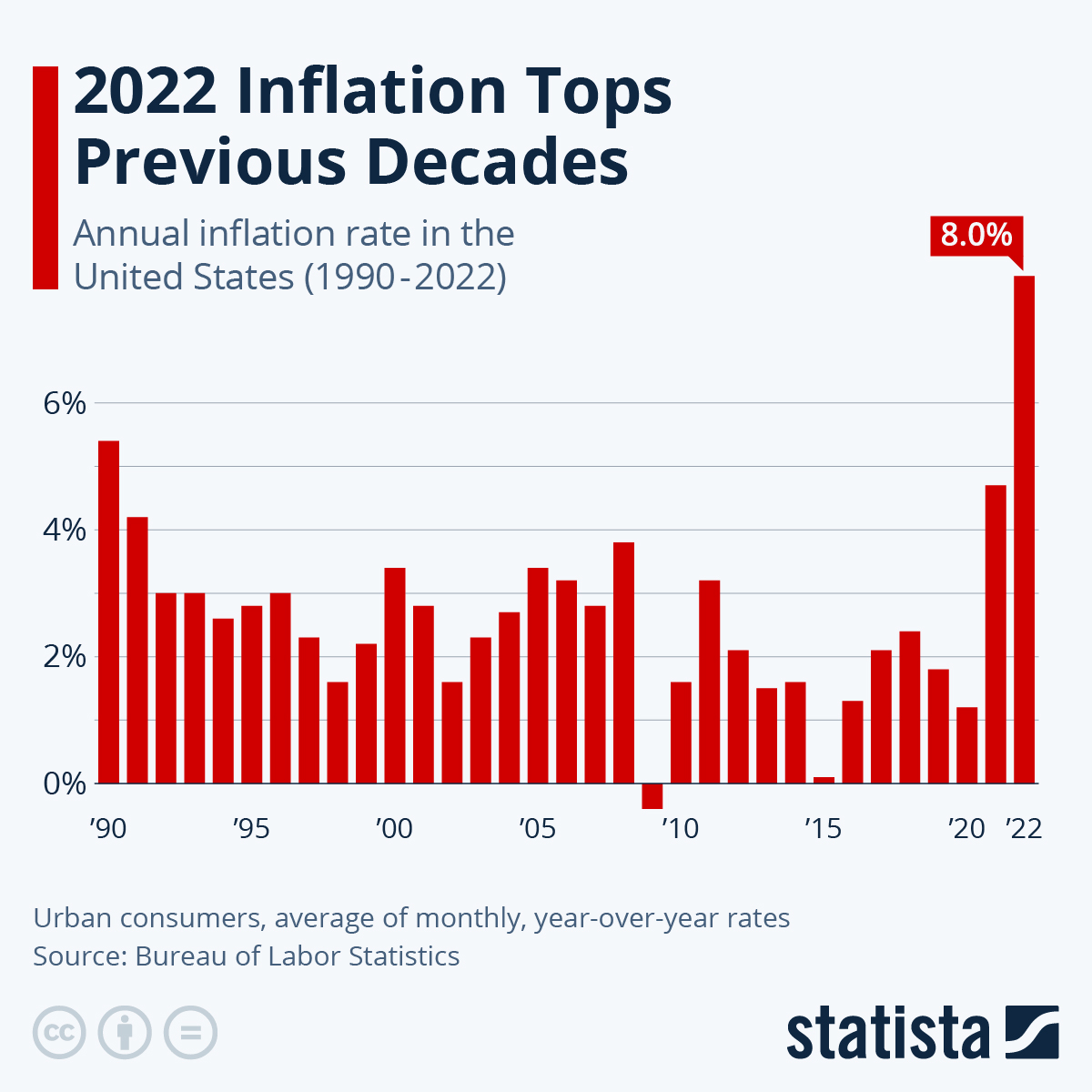

There’s no beating around the bush: everything is getting more expensive. The Consumer Price Index shows in 2022, annual average inflation in the United States hit an all-time high of 8%.

Every element across the supply chain is fighting rising costs:

- The Consumer Brand Association found wholesale prices for consumer-packaged goods brands rose 14.5% since last year

- The price to manufacture factory goods increased by 5.9% over the last year

- The cost of warehouse space has increased by 400%, largely due to merchants holding more inventory and space becoming valuable

- The average cost of a shipping container is four times higher than last year

These increasing costs have a domino impact on consumer prices. To remain profitable, almost three-quarters of ecommerce brands are hiking product prices.

UK-based fashion retailer Next, for example, is warning customers of an 8% price increase in the spring-summer season of 2023.

“Freight cost management has long been a concern for shippers, but it has risen to a new level of importance in recent years. Shippers already faced escalating prices before the pandemic hit owing to our position in the truckload market pricing cycle, and the COVID-19 volatility just made things worse.” —Raine Gui, founder and creative director at Model Chic

#cta-visual-pb#<cta-title>Empower your whole team to make site updates<cta-title>Designed for larger ecommerce teams, Shogun Page Builder Advanced gives you 10+ user seats with unique roles and permissions to scale your content creation efforts.Learn more

Labor shortages

Supply chain technology is evolving rapidly (more on that later). But the supply chain still needs human talent to ensure consistency and growth.

However, hiring and retaining qualified workers is the biggest supply chain challenge for 54% of businesses. Workers are complaining about low wages, voting with their feet, and striking—causing further disruption to already-tumultuous supply chains.

Take UPS, the largest courier company in the world. A labor union representing 350,000 workers is threatening to strike this summer, citing pay and scheduling issues as the driver behind the strike—which could threaten the delivery of millions of parcels.

If strike-related issues go unaddressed, workers could walk out. Retaining those employees is even more painful; the supply chain industry faces a global skills and talent shortage.

Rising customer expectations

The majority of customers are already aware of supply chain problems facing ecommerce merchants. Even Amazon struggles to meet its infamous two- or next-day delivery promises.

But customers don’t have much sympathy; some 44% of customers think the timing of their delivery is extremely important. So much so 83.5% wouldn’t buy from a retailer again if their previous order took too long to arrive.

It’s not just shipping delays that frustrate customers.

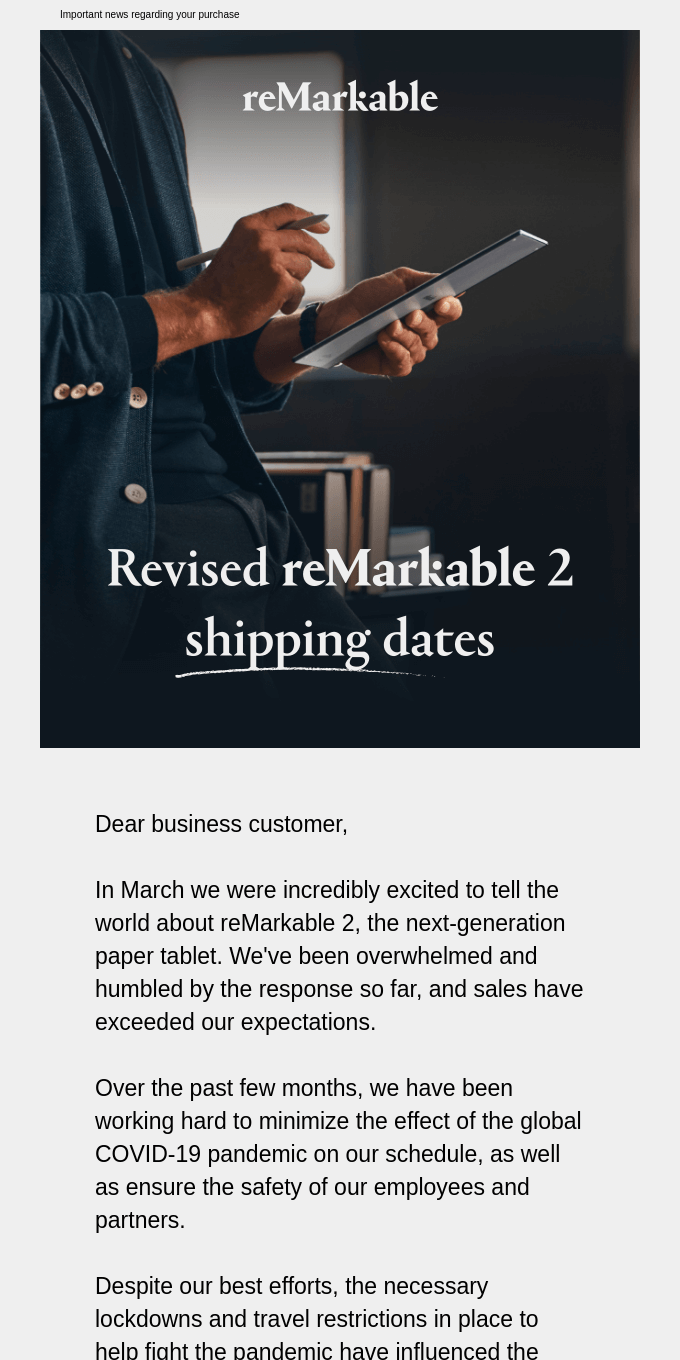

DTC brands aren’t publicly advertising stockouts or supply chain delays. They’re promoting a product as normal and sending apologies post-purchase with revised shipping dates. Forrester predicts brands will lose 50% of sales on these unintentionally back-ordered products.

If you’re feeling the force of these issues, you’re not alone. The vast majority of ecommerce merchants are hurting from at least one of these supply chain challenges. And with pressure unlikely to ease in the coming years, your best bet is to make the entire supply chain more resilient.

#cta-visual-pb#<cta-title>Scale content creation across multiple storefronts<cta-title>Designed for larger brands, Shogun Page Builder Advanced enables your team to copy and clone content across your sub-brands and various storefronts with ease.Learn more

5 supply chain trends to support your growth in 2023

Now we know the challenges facing ecommerce companies, let’s look at the supply chain trends you can capitalize on to succeed.

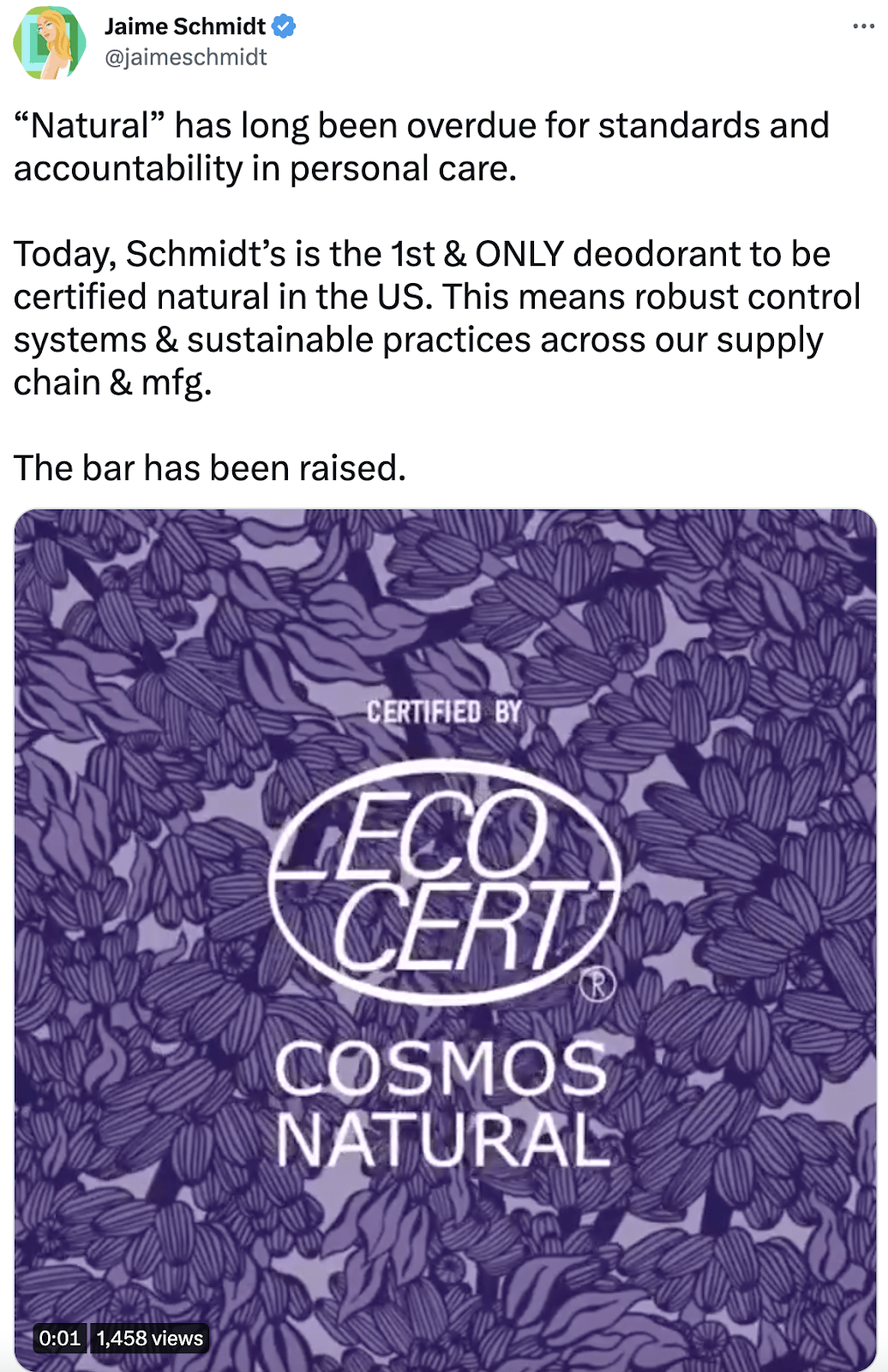

1. Implementing sustainable supply chain practices

With product prices and customer expectations rising, merchants are making their supply chains more sustainable to keep (and retain) customers.

Studies show that one in five US shoppers consider the environmental impact of delivery options when shopping online. Not only are brands paying attention, but they’re making changes:

“We’ve implemented several measures such as prioritizing renewable energy sources, recycling materials, and using reusable packaging when possible. We also work closely with our suppliers to ensure that their practices are aligned with our sustainability goals.” —Todd Saunders, general manager at Big Safety

The good news: you don’t need to emulate Nestle’s strategy of investing $110 million into reducing emissions by optimizing routes, using alternative fuels, or testing more innovative transportation options.

Other smart ways to make your supply chain more efficient include:

- Responsibly sourcing raw materials

- Partnering with already-sustainable third-party logistics providers (3PL)

- Using payment apps like Shop Pay, Carbon Neutral Cart, and Co2ok to offset a shopper’s carbon footprint

2. Investing in nearshoring production

Nearshoring is the process of working with suppliers and manufacturers outside of your own country but within a nearby location.

These countries often share similar time zones and cultures, like the US and Mexico—the latter of which some predict to replace China as a top global manufacturing exporter.

US-based merchants are already reducing their reliance on major exporting countries like China. So much so, 30% have found new suppliers, while 65% of fashion executives are considering nearshoring to address supply chain challenges.

The obvious advantages of nearshoring include:

- Shorter lead times, reducing delays and improving agility

- Parcels have shorter distances to travel, which reduces carbon emissions

- Cut supply chain costs by hiring skilled talent overseas

- It’s easier to strengthen relationships with suppliers who speak the same language, are in the same time zone, and have similar cultures

- Greater control over manufacturing and production processes since it’s easier (and cheaper) to visit nearby warehouses

IKEA is one brand using nearshoring to ensure supply chain continuity. Since 2021, the furniture giant has been nearshoring product production to manufacturers’ locations in Turkey rather than East Asia to better serve stores across Europe.

3. Improve supply chain visibility with warehouse technology

Workers across many industries are concerned that technology will replace their jobs.

That can be the case in the supply chain, but rather than replacing jobs, machine learning and artificial intelligence (AI) software is helping supply chain staff do their jobs better.

Not convinced? McKinsey reports companies that use AI-powered supply chain management can improve logistics costs by 15%, service levels by 65%, and inventory management levels by 35% compared to merchants that don’t.

“I think the trend in ecommerce supply chain will be to automate as much as possible. I’m currently exploring how I can use automation to reduce manual data entry processes, better track inventory, and improve customer service.” —Casey Allen, owner and CEO of Barista Warrior

Digital supply chain software helps merchants get greater visibility over logistics. You can forecast stock, analyze timescales, and improve efficiency—all of which help keep the chain moving, staff happy, and constantly meet customer demands.

It’s no wonder why so many brands are investing in technology to digitize elements of the supply chain:

- Sam’s Club is investing in its use of automated fulfillment to deliver orders faster

- Legacy brands like Walmart and Ford are experimenting with drone delivery services to meet speedy fulfillment expectations and cut costs

- Shopify Fulfillment Network invested in Chuck, a warehouse robot that uses machine learning and AI to pick inventory up to three times faster than the industry standard

- CPG brand Hormel Foods partnered with Crisp, an open-data retail platform, to leverage historical and real-time supply chain data

4. Localize your fulfillment locations

Delays and rising prices are two of the largest supply chain challenges modern ecommerce businesses face.

As Aviad Faruz, CEO of Faruzo, explains, “The biggest challenge is to arrange resources and get them where they need to be. The fact that prices have risen does not imply that buyer demand has changed. Arranging all the resources according to their wants has been an extremely challenging task.”

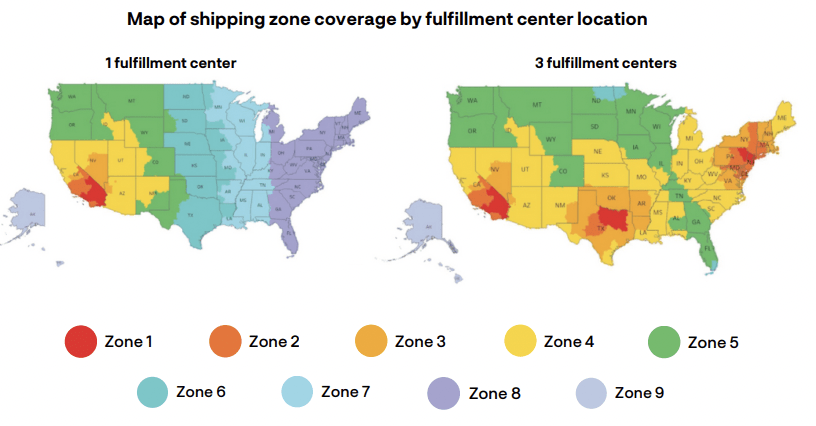

Localizing fulfillment locations alleviates both bottlenecks. By opening several fulfillment locations nearby customers, ShipBob reports businesses can reduce shipping costs by 25% and bring a 13% cost saving to their bottom line.

Big-name brands like Foot Locker use regionalized distribution centers to support areas popular with customers. Department store Macy’s is also turning 35 stores into semi-automated distribution centers to save shipping costs, speed up deliveries, and reduce the need for split shipments.

If you don’t have the budget to invest in fulfillment centers nor use brick-and-mortar locations to manage inventory, consider a 3PL partner that does.

Services like ShipBob, ShipHero, and ShipMonk each have warehouses dotted throughout the country, so you can ship inventory from the location nearest to your customer. This tactic will make your supply chain more sustainable and reduce shipping costs.

“Those with one 3PL in one location are very much at risk. We’ve had to turn off ads and slow down growth for brands with a 3PL with only one location.”—Carolyn Lowe, CEO and founder of ROI Swift

5. Diversify your supply chain strategies

What happens if one part of your supply chain crumbles? It’s a disaster that doesn’t seem too outlandish for many ecommerce companies.

According to Todd Saunders, general manager at Big Safety, “The biggest challenge we face is ensuring our supply chain remains agile and responsive to changes in global demand.

“With the rapid growth of ecommerce, supply chain networks have become increasingly complex and more susceptible to disruption. As a result, we must quickly identify potential problems and act accordingly to minimize disruptions or delays.”

Elements of an agile supply chain to diversify and future-proof include:

- Transportation. More than 30% of brands surveyed by Modern Retail have invested in shipping by air in the last year. Victoria’s Secret, for example, is opting for alternative transportation options after costs rose by roughly $300 million, largely due to its heavy reliance on air freight.

- Fulfillment partners. Disarray in the supply chain industry has forced several logistics companies to cease trading. By forming partnerships with a variety of 3PLs, manufacturers, and suppliers, you ensure continuity if one falls.

- Fulfillment options. Make last-mile logistics more sustainable with omnichannel fulfillment options like buy online, pickup in-store (BOPIS). You save money on shipping; customers can collect parcels at a time that’s convenient for them.

- Warehouse locations. Not only do localized warehouses and fulfillment centers get orders to a customer faster, but there’s less damage if one falls. If a center in Florida is unusable due to hurricane damage, for example, rerouting inventory to the Utah center ensures products still reach customers.

Optimize your global supply chain to thrive in 2023

As you can see, there are various supply chain issues and challenges that merchants will need to navigate through the coming year.

From new technologies to nearshoring production, evaluate your current supply chain to make it more cost-effective and sustainable. It might not sound like a priority right this instant, but the best supply chains—those that ensure business continuity and seamless customer experiences—are resilient.

#cta-visual-pb#<cta-title>Empower your whole team to make site updates<cta-title>Designed for larger ecommerce teams, Shogun Page Builder Advanced gives you 10+ user seats with unique roles and permissions to scale your content creation efforts.Learn more

Elise Dopson

Elise Dopson is a freelance writer for B2B commerce and martech companies. When she's not writing, you'll find her in the Peak Freelance community or on Twitter.